Selecting the right equipment is crucial for excelling in Direct to Fabric (DTF) T-shirt printing, ensuring superior results with accurate color representation and intricate details. Core components include a high-performance DTF printer, durable cutting plotter, lightbox, and heat press machine. DTF offers faster, consistent, and versatile printing compared to DTG, making it ideal for high-volume production runs of T-shirts and accessories. Investing in these tools allows professionals to efficiently manage print jobs and consistently deliver high-quality DTF T-shirt printing services.

“Unleash your creativity with professional DTF T-shirt printing—a game-changer for custom apparel. This comprehensive guide navigates the essential equipment setup, from choosing the right DTG or DTF printer to optimizing your workspace and mastering calibration. Discover the pros and cons of different machines, budget-friendly options, and high-volume production tips. Learn how to organize your studio, maintain print quality, and troubleshoot common issues. Elevate your T-shirt printing journey with these expert insights for exceptional results.”

- Choosing the Right Equipment for DTF T-Shirt Printing

- – Discussion on essential equipment needed

- – Comparisons between different printing machines (e.g., DTG vs. DTF) and their pros/cons

Choosing the Right Equipment for DTF T-Shirt Printing

Choosing the right equipment is paramount when setting up for DTF (Direct to Fabric) T-shirt printing. The process involves transferring designs from a digital file directly onto fabric using heat and pressure, making specialized tools essential. For professionals looking to deliver high-quality results with DTF for t-shirts, investing in top-tier printers designed specifically for this technique is crucial. These machines ensure precise color reproduction and crisp detail, vital for meeting client expectations.

Additionally, a reliable DTF transfer film and compatible ink are critical components of your setup. The right transfer film facilitates easy application and long-lasting adhesion, while high-quality ink yields vibrant colors and ensures the design’s durability after washing. By selecting these core elements thoughtfully, you’ll be well-equipped to handle various print jobs efficiently and consistently, elevating the overall quality of your DTF t-shirt printing services.

– Discussion on essential equipment needed

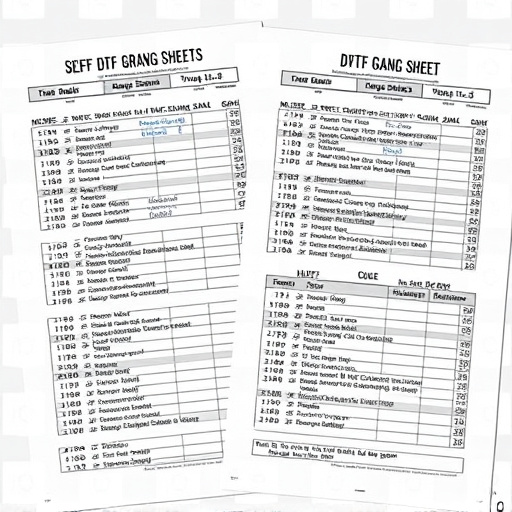

To embark on professional DTF T-shirt printing, several essential pieces of equipment are required. The core setup includes a high-quality DTF printer, which is specifically designed for accurate and precise direct to film (DTF) printing. This technology allows for intricate detail and vibrant colors, making it ideal for creating custom designs on t-shirts. Alongside the printer, you’ll need a durable cutting plotter to meticulously cut out the design from the film, ensuring clean and crisp outlines.

A lightbox is another crucial component, serving as a precise guide for aligning the printed film onto the t-shirt. This step-by-step process demands precision, and a well-lit box aids in achieving seamless results. Additionally, invest in a reliable heat press machine to permanently apply the design to the fabric. With these fundamental equipment in place, you’re well-prepared to navigate the DTF printing world, creating stunning custom T-shirts for any occasion.

– Comparisons between different printing machines (e.g., DTG vs. DTF) and their pros/cons

Direct-to-garment (DTG) and Direct-to-form (DTF) printing are two distinct methods in the T-shirt printing industry, each with its unique advantages and considerations. DTG printing involves spraying ink directly onto the fabric, typically using a digital printer, offering vibrant colors and fine detail. This method is ideal for small batch sizes and complex designs as it allows for a wide range of artistic expression. However, DTG printing may not be as efficient for larger orders due to setup time and potential ink-bleeding issues on certain fabrics.

On the other hand, DTF printing utilizes custom sheets to transfer heat-pressed designs onto garments, ensuring sharp lines and a more durable print. It is particularly well-suited for printing on hoodies, caps, and other accessories as it provides a professional, long-lasting finish. While DTF may not offer the same level of color vibrancy as DTG, it excels in speed and consistency, making it a preferred choice for high-volume production runs. Custom sheets for heat pressing designs onto garments further enhance this method’s versatility, accommodating various fabric types and allowing for more intricate artwork.

Setting up for professional DTF T-shirt printing requires an investment in quality equipment, including a reliable DTF printer, a robust ink system, and precise application tools. By understanding the pros and cons of different machines and choosing the right setup, you can achieve consistent, high-quality prints that meet the demands of modern customization. Remember, the right equipment is key to unlocking your creativity and delivering exceptional results in the DTF T-shirt printing process.