Direct to Fiber (DTF) T-shirt printing offers cutting-edge custom apparel creation with vibrant, high-quality prints on various materials and styles. Efficient management requires meticulous file preparation, including optimizing design files for accurate color profiles and resolution, using industry-standard software, and implementing robust DTF color matching practices. Regular color profile testing, a well-organized order tracking system, client communication, and prompt issue resolution enhance overall efficiency. Best practices like organizing workflows, maintaining a systematic file management system, investing in durable UV DTF transfers, and regularly updating design libraries streamline the process for consistent, high-quality DTF printed shirt outcomes.

“Unleash the potential of DTF T-shirt printing with a robust order management system. This comprehensive guide navigates the intricate workflow, offering insights into efficient strategies. From understanding the unique DTF process to implementing best practices, you’ll learn to streamline your operations. Master order handling, optimize production, and deliver exceptional customer experiences in the dynamic world of DTF T-shirt printing.”

- Understanding DTF T-Shirt Printing Workflow

- Strategies for Efficient Order Management

- Best Practices to Streamline Your Process

Understanding DTF T-Shirt Printing Workflow

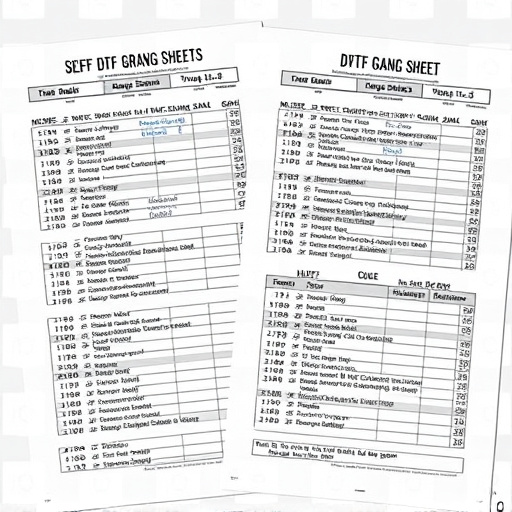

The DTF (Direct to Fiber) T-shirt printing process offers a cutting-edge approach to custom apparel creation. It’s a direct printing method where designs are transferred onto a special film, which is then cured using UV light before being applied to the fabric through heat pressing. This technology allows for vibrant, high-quality prints on various materials and styles of t-shirts. Understanding this workflow involves grasping several key steps: first, preparing your dtf artwork transfers by ensuring they meet specific requirements, such as resolution and format; then, uploading your own gang sheet (a layout file) to integrate your designs onto the t-shirt templates accurately; followed by pre-press checks to verify color accuracy and design placement.

Once your dtf artwork transfers are ready, they are precisely positioned over the selected t-shirt styles, ensuring the print aligns perfectly with the garment’s cut and design intent. This meticulous process is what sets DTF T-shirt printing apart, enabling businesses to offer unique, customized shirts with intricate details and vivid colors. By navigating this workflow effectively, from file preparation to final printing, you can ensure high-quality dtf printed shirts that meet customer expectations.

Strategies for Efficient Order Management

Managing orders efficiently in a DTF (Direct-to-Fabric) T-shirt printing workflow is key to running a successful business. The process begins with proper DTF file preparation. Ensuring that design files are optimized for printing, with accurate color profiles and resolution, streamlines the production process. Using industry-standard software and templates can significantly reduce errors and delays at this stage.

Additionally, implementing robust DTF color matching practices is vital for consistent quality. This involves calibrating your printing equipment to match the colors precisely with the design files. Regularly testing and maintaining your color profiles ensures that each DTF printed shirt meets client expectations. A well-organized system for tracking orders, keeping clients informed, and promptly addressing any issues further contributes to efficient order management in a DTF T-shirt printing workflow.

Best Practices to Streamline Your Process

Implementing best practices can significantly streamline your DTF T-shirt printing process, ensuring efficiency and high-quality outcomes. Firstly, organize your workflow by prioritizing tasks based on order urgency and complexity. This helps in managing time effectively and meeting deadlines promptly. Additionally, maintain a systematic file management system for all DTF transfer designs; well-organized folders with clear naming conventions make it easier to locate and access ready-to-press transfers, reducing preparation time.

Another crucial practice is investing in high-quality UV DTF transfers known for their exceptional durability. Using these pre-made transfers not only saves time but also guarantees consistent print quality across orders. Regularly updating your transfer library with various designs and styles allows you to adapt to client requests efficiently, enhancing your overall productivity in the DTF T-shirt printing process.

Managing orders efficiently in a DTF T-shirt printing workflow is key to ensuring customer satisfaction and business growth. By understanding the unique aspects of this printing process, implementing strategic order management techniques, and adhering to best practices, you can streamline your operations, reduce turnaround times, and deliver high-quality products consistently. Optimize your workflow, enhance communication, and focus on continuous improvement to excel in the competitive world of DTF T-shirt printing.