DTF T-shirt Printing revolutionizes custom apparel by offering vibrant, precise prints on diverse fabrics via a specialized heat press. It supports complex designs, enables on-demand services, and streamlines production with faster turnaround times and eliminated setup costs, catering to both small and large orders.

“Discover the future of custom apparel with Direct to Fabric (DTF) T-shirt printing. This innovative method is revolutionizing the way businesses cater to personalized merchandise demands. In this article, we explore the benefits of integrating DTF fulfillment into your supply chain. From understanding the technology behind it to breaking down the step-by-step process, you’ll gain valuable insights into why DTF printing is a game-changer for custom apparel. Elevate your brand and enhance customer satisfaction with this cutting-edge technique.”

- Understanding Direct to Fabric (DTF) Printing

- Benefits of Custom Apparel Fulfillment

- DTF T-Shirt Printing: A Step-by-Step Process

Understanding Direct to Fabric (DTF) Printing

Direct to Fabric (DTF) Printing is a cutting-edge technique revolutionizing the custom apparel industry. Unlike traditional printing methods that rely on pressing designs onto fabric, DTF directly applies ink to the garment’s surface using a specialized heat press. This innovative process allows for high-quality, vibrant prints on a wide array of fabrics, making it an ideal choice for creating unique and personalized T-shirts.

With DTF for t-shirts, entrepreneurs and designers can effortlessly bring their creative visions to life. The precision and speed of the heat press ensure consistent results, enabling efficient production of custom apparel. Moreover, this method is suitable for various types of designs, from simple text to intricate graphics, catering to diverse customer preferences. By embracing DTF printing, businesses can offer on-demand services, satisfying the growing demand for personalized clothing in today’s market.

Benefits of Custom Apparel Fulfillment

Custom Apparel Fulfillment with DTF (Direct to Fabric) T-shirt Printing offers a multitude of benefits for businesses and individuals alike. One of the key advantages is its ability to cater to unique design preferences, allowing for complete customization. Whether it’s printing on demand or setting up bulk production, DTF technology enables efficient creation of personalized apparel. This method is not just limited to t-shirts; it can also be applied to other garments like hoodies, ensuring a versatile and inclusive service.

Additionally, DTF T-shirt Printing streamlines the process, reducing turnaround times. It eliminates the need for complicated setup processes, making it suitable for both small-scale orders and large-volume production. This efficiency, coupled with high-quality prints, results in satisfied customers. Furthermore, this technology supports a wide array of fabric types, ensuring that designs can be perfectly replicated on various materials, from soft cotton to robust polyesters.

DTF T-Shirt Printing: A Step-by-Step Process

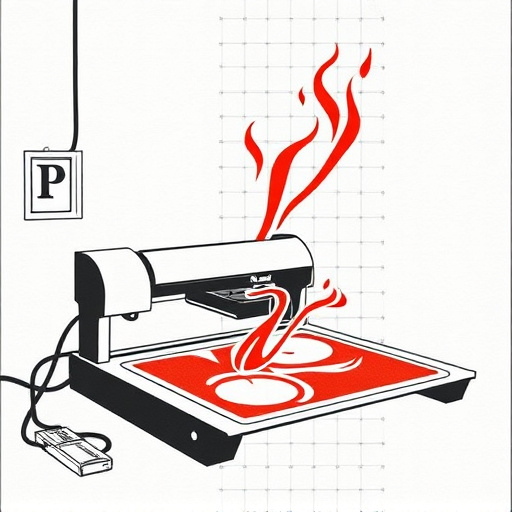

DTF T-Shirt Printing is a direct-to-fabric (DTF) method that allows for precise and vibrant printing on textiles. Here’s a step-by-step breakdown of the process:

1. Preparation: Start by designing your artwork, ensuring it’s in high resolution with the correct color profile. This design will be transferred onto the T-shirt. For light fabrics, consider using DTF printing techniques specifically tailored for these materials to achieve optimal results.

2. Setting Up: Load the T-shirts into the printing machine. These machines use a heat press to apply the ink directly onto the fabric. Ensure proper alignment and positioning of the shirts to maintain consistency in printing quality.

3. Ink Application: Heat up the ink and precisely deposit it onto the T-shirt using the DTF printing method. This involves forcing hot air through a mesh screen, creating a fine mist of ink that lands directly on the fabric. The process is fast and efficient, making it ideal for small to medium production runs or custom apparel fulfillment.

4. Curing: After printing, cure the ink by heating the T-shirt briefly in the press. This step ensures the ink bonds permanently with the fabric, creating a long-lasting, high-quality print. For clothing brands looking to personalize their products, DTF printing allows for the creation of unique and intricate designs, including detailed logos.

5. Quality Control: Finally, inspect each printed T-shirt for any defects or misprints. This step is crucial in maintaining the quality and reputation of your apparel brand.

Custom apparel fulfillment using Direct to Fabric (DTF) printing offers a streamlined and efficient solution for businesses. By leveraging this innovative technology, companies can cater to the growing demand for personalized merchandise with ease. DTF T-shirt printing allows for intricate designs, fast turnaround times, and cost-effectiveness, making it an ideal choice for various industries. Its simplicity and versatility ensure that brands can efficiently manage their inventory and deliver high-quality products to their customers.