Direct-to-film (DTF) transfers are transforming the t-shirt decoration industry by offering detailed, vibrant designs with a streamlined process. Beginners can master DTF fundamentals to create high-resolution prints on any fabric. Key steps include selecting the right materials, using specialized software for design, and carefully positioning and heat-pressing the film onto shirts. DTF's advantages—such as superior color quality, detail retention, cost-effectiveness, and quick turnaround times—make it ideal for small businesses and individual artists. By following best practices, including pre-treating fabric and conducting test prints, users can achieve exceptional DTF transfers on t-shirts.

Discover the world of Direct-to-Film (DTF) transfers for creating unique and vibrant t-shirt designs. This beginner’s guide explores how DTF technology offers a revolutionary approach to custom clothing. From understanding the process to choosing the right materials, you’ll learn how to achieve exceptional results. We’ll walk you through each step, from design selection to application, unlocking endless creative possibilities with this game-changing technique, all while ensuring high-quality, indelible prints on your t-shirts.

- Understanding Direct-to-Film Transfers: A Beginner's Guide

- The Advantages of DTF for T-Shirt Decorating

- Choosing the Right Materials and Equipment

- Step-by-Step Process of Applying DTF Designs to T-Shirts

- Best Practices for Achieving High-Quality Results

- Exploring Creative Possibilities with DTF on T-Shirts

Understanding Direct-to-Film Transfers: A Beginner's Guide

Direct-to-film (DTF) transfers are a cutting-edge method revolutionizing the art of decorating t-shirts. Unlike traditional printing techniques, DTF involves transferring ink directly from a digital file onto fabric using specialized equipment. This process allows for an incredibly detailed and vibrant end product, making it a favorite among designers and entrepreneurs alike.

For beginners, adopting DTF offers a world of creative possibilities. It streamlines the design-to-product transformation, enabling easy customization and one-of-a-kind designs. With access to high-resolution prints and precise control over ink placement, you can create stunning visuals that pop on any fabric. This guide is your starting point, providing insights into the fundamentals of DTF transfers to help you embark on this exciting journey.

The Advantages of DTF for T-Shirt Decorating

Direct-to-film (DTF) transfers offer a multitude of advantages for decorating t-shirts, making them a popular choice among designers and businesses alike. One of the key benefits is their exceptional quality; DTF prints deliver vibrant colors and crisp details, ensuring that designs look as good as they do on high-resolution screens. This method allows for complex artwork, intricate patterns, and even full-bleed prints, providing endless creative possibilities for customizing t-shirts.

Additionally, DTF transfers are highly versatile, suitable for a wide range of fabrics and styles. They can be applied to various materials, including cotton, polyesters, and blends, making them ideal for creating unique, personalized garments. The direct application process eliminates the need for screens or plates, which streamlines production and reduces setup times. This efficiency contributes to cost-effectiveness, especially for small-batch production or one-off designs, ensuring that businesses can offer tailored, high-quality products without breaking the bank.

Choosing the Right Materials and Equipment

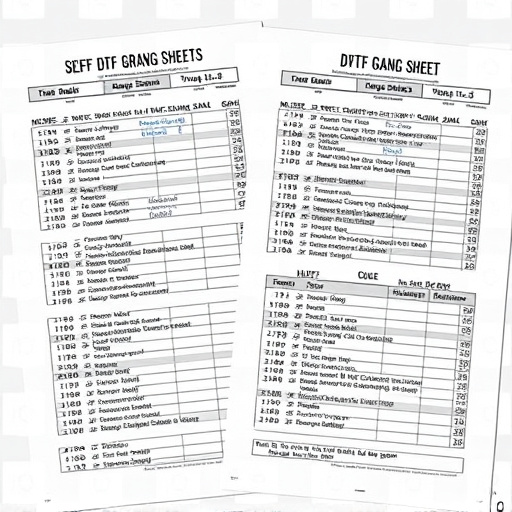

When it comes to choosing materials and equipment for direct-to-film (DTF) transfers on t-shirts, precision and quality are paramount. Opt for high-resolution printers capable of producing crisp, detailed designs. The right film transfer sheets, compatible with DTF technology, ensure smooth application and long-lasting durability on various fabrics.

Invest in a diverse range of tools, including squeegees, heat presses, and protective gear. A clean work area is essential; consider using a dedicated station equipped with proper ventilation to handle the chemicals involved. Additionally, staying stocked with a variety of ink colors and finishes allows for creative expression in your shirt designs.

Step-by-Step Process of Applying DTF Designs to T-Shirts

Direct-to-film (DTF) transfers offer a precise and efficient method for decorating t-shirts, allowing designers to achieve high-quality results with minimal effort. The step-by-step process begins with designing or selecting an image using specialized software, ensuring it meets the required specifications for DTF printing. Once the design is finalized, it’s sent to a compatible printer, which produces a negative film layer overlaying the chosen t-shirt. This film is then carefully positioned over the shirt and heat-pressed, fusing the design onto the fabric.

After the pressing, the film is carefully peeled away, leaving a vibrant, long-lasting design on the t-shirt. The process ensures precise color reproduction and detail retention, making DTF an excellent choice for creating unique, eye-catching garments. This method also allows for quick turnaround times, enabling small businesses and individual artists to produce custom shirts efficiently.

Best Practices for Achieving High-Quality Results

To achieve high-quality results with direct-to-film (DTF) transfers on t-shirts, start by selecting top-tier film and ink compatible with your printing method. Using premium materials ensures better adhesion, vibrant colors, and longer-lasting prints. Pre-treating the t-shirt fabric is another best practice; this prepares the surface for optimal ink absorption, enhancing the final image quality.

When designing your artwork, keep in mind that resolution is key. High-resolution images (300 DPI or better) ensure sharp details and smooth gradients. Additionally, proper color profiles and modes (CMYK typically for printing) contribute to accurate representation on the final product. Test prints are also crucial—they allow you to tweak settings and adjust designs before mass production, ensuring consistently excellent results with your DTF transfers.

Exploring Creative Possibilities with DTF on T-Shirts

Direct-to-film (DTF) transfers have unlocked a world of creative possibilities for decorating t-shirts. This cutting-edge technology allows for intricate, high-resolution designs that can be applied directly to various fabrics, including cotton, polyester, and more. Artists and designers are no longer limited to traditional printing methods; instead, they can embrace a broader palette of colors, textures, and effects.

With DTF, the sky’s the limit when it comes to crafting unique t-shirts. From eye-catching graphics and detailed illustrations to subtle patterns and personalized messages, this method offers versatility for every taste and style. Whether you’re an entrepreneur looking to launch a trendy clothing line or an individual seeking to express your creativity, DTF transfers provide an accessible way to transform ordinary t-shirts into extraordinary pieces of art that stand out in any crowd.